Applications - All > Applications - General

Importance of measuring correctly for proper fitting exhaust blankets

The importance of measuring correctly the exhaust components to ensure a proper fitting exhaust blankets cannot be over-emphasised. This is especially true for radius, diameter and circumference measurements. For example, an error in measuring the diameter results in an error of over 3x (3.14x to be exact) in the circumference.

If the measurement is larger than actual, that will result in a slightly larger and loose fitting blanket, which may be acceptable and may be corrected in the field with some compression strapping or overlapping of edges.

But if the measurement is short, then gaps can exist, and this cannot be easily corrected except by adding an additional gusset piece, or even a complete rework of that blanket piece - adding cost and time to the project.

Below is an example of a case where measurements were not double checked before approving for a build.

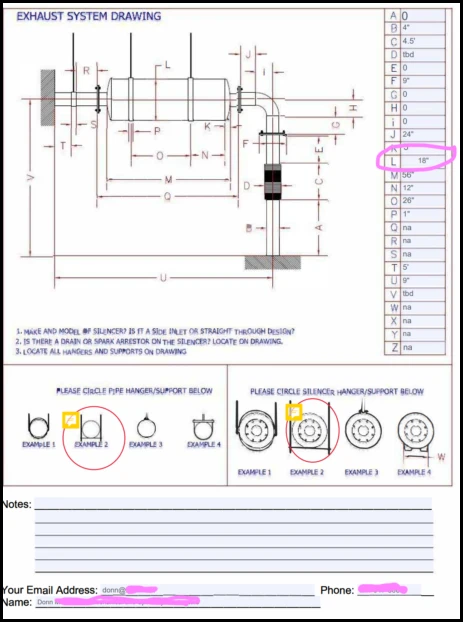

Figure 1 is the original dimensions submitted by the customer. We will call him Donn, as that is his real name. Note in particular the dimension for the diameter of the silencer. It is marked in his sheet as 18 inches. The circumference of an 18 inch diameter is 56.52 inches.

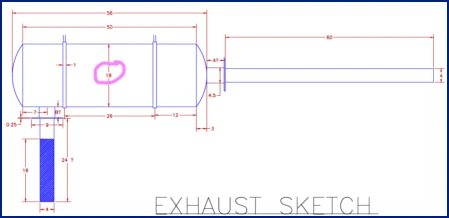

Figure 2 is the confirmation drawing sent back to the customer for verification of the dimensions.

Figure 3 shows the circumference measured by Donn after he notices the blanket does not fit.

Fig 1 - Original Dimensions from Donn. Diameter = 18 inches

Fig 2 - Confirmation drawing sent to customer for checking - with the 18 inch diameter from his original template highlighted.

Fig 3 - Measured circumference after blanket delivery is 4 foot 9-3/4" = 57.75". 57.75 divide by 3.14 = 18.39 inch diameter. Difference in circumference in the initial provided dimension of 18" diameter results in blanket being 1.23" short in circumference.

57.75

-56.52

1.23"