Main Form Products > Sleeve Groups > Thermal Insulating and Protective Sleeve

Thermal Insulating & Protection Sleeves

"Thermal Insulating and Protection Sleeve" Sub-category

Thermal Insulating and Protection Sleeve Summary

Sleeve to protect wires, cables, tubing, hoses and pipes from heat loss or heat gain.

Sleeve to protect wires, cables, tubing, hoses and pipes from environmental exposure, contamination, fluids, dirt, etc.

Sleeves to protect personnel from burns by accidental contact with hot pipes or hoses.

Available in a variety of materials including kevlar, nomex, silicone rubber, E-glass and S-glass fiberglass, basalt, silica and alumina.

- plain sleeves

- heat treated sleeves

- saturated sleeves (silicone resin, acrylic resin - (available in colors),

- oleoresinous varnish impregnated sleeve

- vermiculite coated fiberglass sleeves

Please contact our technical support for application help if your application includes exposure to direct flame, fire, liquid metals, spatter, slag, etc. We have other protection solutions to go along with these insulation sleeves.

Thermal Insulated Sleeve Wrap for Pipe and Hose - Heat Loss and Freeze Protection - OSHA Burn Protection

200°F / 93°C High Temperature Heat Resistant Thermal Insulating - Also Freeze Protection

Custom fabricated insulated tape wrap for pipe, hose and line protection: heat loss and freeze protection. Provides personnel protection to meet OSHA requirements.

May be cut in the field to shorter lengths.

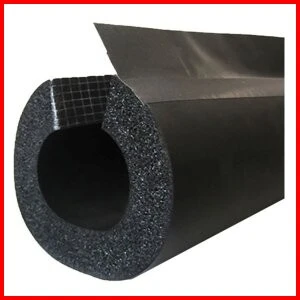

Closed Cell Sponge Foam Thermal Insulation Sleeve

Thermal Insulating

220°F / 104°C Continuous Exposure: Higher Intermittent

A premium thermal insulation sleeve with an effective vapour barrier PVC coating and an aggressive adhesive strip closure.

Supplied in a 6 foot / 1.82 metre stick. Provides R-3 insulation value. Wall thickness is 1/2" / 13 mm.

Effective condensation prevention for water and refrigeration lines. Mold and mildew resistant.

Compatible with heating cables and tapes for freeze protection.

Product Group Code: S-INSULPIPE

Protection sleeve wrap for HVAC Insulation Foam

With the introduction of new building code regulations regarding protection of foam insulation on HVAC lines, this light weight wrap assists installers with code compliance.

Constructed of a tightly woven breathable polyester shell that offers protection from wind, rain, mildew, UV rays and abrasion. The extra wide hook and loop closure assists in covering multiple diameters quickly and easily for a tight fit.

Building Code Compliant: C 403.2.10.1 & R 403.4.1

Braided Kevlar® Aramid Sleeve for wire cable hose protection

320°F / 160°C Continuous Exposure: Higher Intermittent

FlameShield™ high temperature and heat resistant Kevlar aramid sleeve is fabricated from high quality yarns that will not burn and will withstand continuous exposure to temperatures of 320°F / 160°C. It provides excellent protection for industrial wires, cables, hoses (hydraulics), tube and pipes and also provides thermal insulation and personnel protection. Kevlar is highly cut resistant, making this sleeve especially suited where contact with sharp edges is a concern.

This sleeve is available in:

- Standard Wall - natural (yellow)

- Heavy Duty Wall - natural (yellow)

- Medium Wall - colored (Safety Orange, Black, Blue, Red, Green, Yellow (natural))

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. The Standard sleeve is highly flexible and conformable while the Heavy Duty version is stiffer but still very flexible.

Both sleeves do experience end fray when cut as there is no binder present in the sleeve; there are several methods of reducing the fray: please visit our FAQ section for further information.

Product Group Codes: S-K, S-K-HD, S-K-C

For S-K standard wall sleeve:

For S-K-HD Heavy Duty wall sleeve:

Braided Nomex® sleeve for wire cable & hose protection

High Temperature, Heat & Flame Resistant and Thermal Insulating

450°F / 232°C Continuous Exposure: Higher Intermittent

FlameShieldä high temperature and heat resistant Nomex® sleeve is fabricated from high quality yarns that will not burn and will withstand continuous exposure to temperatures of 450°F / 232°C. (Melting/disintegration temperature of 662°F / 350°C) provides excellent protection for industrial wires, cables, hoses (hydraulics), tube and pipes and also provides thermal insulation and personnel protection.

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable.

Product Group Code: S-NMX

Nomex® split sleeve wrap for wire cable & hose protection

High Temperature, Heat & Flame Resistant and Thermal Insulating

450°F / 232°C Continuous Exposure: Higher Intermittent

FlameShieldä high temperature and heat resistant Nomex® split sleeve wrap is fabricated from high quality yarns that will not burn and will withstand continuous exposure to temperatures of 450°F / 232°C. (Melting/disintegration temperature of 662°F / 350°C) provides excellent protection for industrial wires, cables, hoses (hydraulics), tube and pipes and also provides thermal insulation and personnel protection.

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable.

Product Group Code: S-NMX-SP

Silicone Sponge Foam Thermal Insulation Sleeve

High Temperature, Heat & Flame Resistant and Thermal Insulating

428°F / 220°C Continuous Exposure: Higher Intermittent

ThermaSleeveä high temperature and heat resistant silicone sponge foam sleeve provides protection and insulation up to 500F / 260C. Fabricated as a closed-cell low density sponge/foam with a low k factor (high insulation factor).

Available as a continuous sleeve and as a slit sleeve for retrofit installation.

Custom made in any ID and OD, or standard sizes of .5" ID, .75" ID, 1" ID, 1.25" ID, 1.5" ID with .5" wall thickness.

Product Group Code: S-SR-SF

Silicone Rubber Round Tubing / Sleeving - Oxide-Red High Temperature Heat Chemical Resistant

460°F / 237°C Continuous Exposure: Higher Intermittent

We offer several versions of silicone rubber tubing/sleeving: Natural/Clear in small sizes, Oxide-Red in a mid-range of sizes, Oxide-Red large size, Star tubing for fastener thread protection, and food grade FDA tubing.

This high temperature silicone rubber tubing is manufactured to exacting standards from our specialty formulation of high-temperature silicone. Industrial Silicone Tubing is used commonly to convey and transfer liquids, air or gases and can also protect wires and hoses from high temperature environments.

Silicone rubber tubing can also be used as a mask to protect bolt and screw threads in painting and powder coating operations, and due to the high temperature rating, can often be reused multiple times.

Due to the non-stick characteristics of silicone rubber, molten metal, solder drips and weld splatter / grinding sparks do not generally stick to the silicone tubing.

Red Tubing: Download PDF Catalog Page

Silicone Rubber Round Tubing / Sleeving - Natural Translucent - High Temperature Heat Chemical Resistant

460°F / 237°C Continuous Exposure: Higher Intermittent

Natural Translucent silicone tubing is available in a range of sizes from .040" ID up to 0.312" ID.

Our high temperature silicone rubber tubing is manufactured to exacting standards from our formulation of high-temperature silicone. Industrial Silicone Tubing is used commonly to convey and transfer liquids, air or gases and to protect wires and hoses from high temperature environments.

High temperature silicone rubber tubing can also be used as a mask to protect bolt and screw threads during painting and powder coating operations, and due to the high temperature rating, can often be reused multiple times.

Due to the non-stick characteristics of silicone rubber, molten metal, weld splatter and grinding sparks do not stick to the silicone tubing.

Translucent Tubing: Download PDF Catalog Page

Fiberglass Thermal Insulating Sleeve with Silicone Rubber Barrier Coating - Firesleeve - Hose & Pipe Protection

High Temperature, Heat, Flame & Fire Resistant

500°F / 260°C Continuous Exposure

800°F / 426°C Short Term Exposure

2200°F / 1205°C Excursions

3000°F / 1650°C Peak Exposure

FlameShield™ Firesleeve knit and braid fiberglass sleeves offer excellent thermal insulation and also environmental protection due to the silicone rubber barrier coating.

Meets 14 CFR 25.869(a)(4); Appendix F, Part 1(b)(7) (60-degree flammability Test) Aviation flammability standrds. This sleeve can be double layered and is also available with many closure styles such as hook and loop, snaps and zippers.

Smaller sizes of FlameShield firesleeve are highly conformable as seen in the photo to the right - it can be easily tied into a knot.

Insulated Sleeve Wrap for Steam Pipe and Hose - Thermal Insulating - OSHA Burn Protection

500°F / 260°C High Temperature Heat Resistant Thermal Insulating - Also Freeze Protection

Custom fabricated insulated wrapping tape for pipe, hose and line protection: high temperature protection and cold temperature protection. Excellent thermal protection and energy saving for boiler piping and steam pipe applications. Also provides thermal insulation and protection to flexible hoses and lines, and rigid lines and piping. Provides personnel burn protection to meet OSHA requirements.

The outer cover is a 32oz/yd2 silicone rubber coated fiberglass. This outer fabric can also be supplied meeting NRC 1.36 specifications. The insulation layer and outer protection layer also meets MIL-I-24244 specifications.

The insulation layer is can be either 1/4", 1/2" or 3/4" thick fiberglass. The 3/4" thickness is a combination of 1/4" and 1/2" insulation layered and stitched.

An optional liner of PTFE coated fiberglass fabric provides additional protection of the insulation layer, especially useful if the tape will be removed and re-installed multiple times, or to prevent wear of the needled insulation and reducing the fibers from becoming free in the area of use. This insulated pipe and hose wrap tape is sewn with high temperature fiberglass thread. A hook and loop fastener is added on the edges of the tape, allowing for easy closure and removal - allowing for easy inspection of the underlying hose, line or piping. The standard hook and loop is nylon; nomex and stainless steel closure versions are available.

May be installed longitudinally or spirally over pipes, hoses, wires and cables.

Supplied in 20 foot lengths. May be cut in the field to shorter lengths.

Fiberglass Braided Sleeve with soft PTFE dispersion infusion

550°F / 287°C Continuous Exposure: Higher Intermittent

FlameShieldä This high temperature, heat / chemical resistant and thermal insulating PTFE coated fiberglass sleeve offers the advantage of a non-asbestos material with a higher temperature range and with excellent resistance to almost all solvents, caustics and acids.

The base fiberglass fabric is rated to 1000°F / 537°C while the PTFE coating melting point is 620°F / 327°C.

Available in 1/16" (thin wall) and 1/8" (thick wall) wall thickness.

Inside Diameters available from 0.25" up to 5.0".

The PTFE is applied to the sleeve by dipping the sleeve through an immersion tank of liquid PTFE dispersion. The sleeve is then air dried and high temperature sinterized, flowing the PTFE throughout the fiberglass filaments. The result is a PTFE coating on the sleeve which is soft, robust and flexible; however, it can be abrasively removed from the sleeve with aggressive fingernail scraping, resulting in a thinner and thinner layer of ptfe remaining with each pass. The coating process also causes the yarns to be sealed and the small gaps between the yarns filled, resulting in an almost air-tight / liquid-tight sleeve wall.

Fiberglass woven cloth with PTFE resin impregnation and Hook & Loop Closure

550°F / 287°C Continuous Exposure: Higher Intermittent

FlameShieldä high temperature, heat / chemical resistant PTFE coated fiberglass sleeve with hook & loop closure offers the advantage of a non-asbestos material with a higher temperature range and with excellent resistance to almost all solvents, caustics and acids.

The PTFE coated fiberglass sleeve is an excellent wire, cable, hose, pipe and tube protective cover providing insulation value, energy savings and personnel protection.

The base fiberglass woven fabric is rated to 1200°F / 647°C while the PTFE coating melting point is 620°F / 327°C.

Woven Fiberglass Sleeve Thermal Insulation with Hook and Loop Closure

High Temperature, Heat & Flame Resistant and Thermal Insulating

1200°F / 648°C Continuous Exposure: Higher Intermittent

InSulTape is a woven fiberglass tape used as a sleeve, available in 1/16, 1/8 or 1/4" thickness, that has a Velcro Brand Hook and Loop Closure added so it can be wrapped around pipes and hoses without disconnecting an end. Can be retrofitted to existing pipe and hose.

Fabricated from high quality type E-fiberglass that will not burn and will withstand continuous exposure to temperatures of 1200°F / 648°C. It provides excellent protection for industrial wires, cables, hydraulic hoses, tube and pipes and also provides thermal insulation and personnel protection.

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18. This product is 100% Asbestos free.

Available By-The-Foot and in 100 foot lengths. Minimum order value may apply to By-The-Foot quantities.

Technical Specifications

Fiber Type: E Glass

Specific Gravity: 2.54-2.69

Breaking Tenacity: 1.71 gf/TEX. Std. 1.71 gf/TEX Wet

Effect of Heat: Will not burn; Retains 75% tensile at 343°C; Softens at 732-877°C; Melts at 1121-1182°C

Tensile Strength: 450,000-500,000 psi.

Effect of Acids and Alkalis; Resistance to acids is fair. Good resistance to most alkalis.

Breaking Elongation: 4.81% Std. 4.81% Wet

Elastic Recovery: 100%

Effect of Bleaches and Solvents: Unaffected

Average Stiffness: 2824.3 cn/TE

Carbon Fiber Braided sleeve for wire cable & hose protection and composite structure construction

High Temperature, Heat & Flame Resistant

1000°F / 537°C Continuous Exposure: Higher Intermittent

FlameShieldä carbon fiber (fibre) braided sleeve is used to protect wires, cables and hoses. Also used to support wires, cables and hoses by forming the sleeve into a composite structure.

Graphite Coated Braided Fiberglass sleeve for wire cable & hose protection

High Temperature, Heat & Flame Resistant

1100°F / 593°C Continuous Exposure: Higher Intermittent

FlameShieldä high temperature, heat and flame resistant and thermal insulating graphite coated braided fiberglass sleeve will withstand temperatures of 1100°F / 593°C continuous exposure. The base high temperature and heat resistant braided fiberglass sleeving is fabricated from high quality type E fiberglass that will not burn. The sleeve is then coated with graphite, adding lubrication and additional protection from splatter and molten metal attachment. This high temperature insulation sleeve protects wire, cable, hose, pipe and tubing, along with providing energy savings and personnel protection.

This sleeve resists molten splash and welding splatter very well as it cannot stick to the graphite.

Exhaust pipe protection sleeve - Engine & generators - personnel protection

High Temperature, Heat & Flame Resistant and Thermal Insulating - For Automotive / Truck / Bus / Marine / Military / Construction / Mining Vehicles

1200°F / 648°C Continuous Exposure: Higher Intermittent

BlackMaxä Exhaust Pipe Sleeve is a high temperature and heat resistant fiberglass braided sleeve, fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1100°F / 593°C. With an acrylic saturant, this sleeve is easy to handle, and is designed to provide burn protection to personnel from casual contact to the exhaust piping risers on transport truck engines and on generator installations. Typically held in place with stainless steel band clamps.

This sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The black color hides dirt and grime contamination.

The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18.

· Helps maintain exhaust gas temperatures in order to meet regulatory requirements.

· Knitted design allows for high conformability.

· Can be fabricated with apertures to accommodate brackets and mounting pads.

· Available in pre-cut or continuous lengths.

· Expandable and durable - provides ease of installation.

· Conforms to bends, elbows, flex sections and flanges.

· Suitable for Fixed Generators, Marine Engines and Generators, Automotive, Truck,

Bus, Construction and Mining equipment.

· Knitted design allows for high conformability.

· Can be fabricated with apertures to accommodate brackets and mounting pads.

· Available in pre-cut or continuous lengths.

· Expandable and durable - provides ease of installation.

· Conforms to bends, elbows, flex sections and flanges.

· Suitable for Fixed Generators, Marine Engines and Generators, Automotive, Truck,

Bus, Construction and Mining equipment.

Knitted Fiberglass Sleeve - Premium Grade - Wire Cable Hose Pipe Protection

High Temperature, Heat & Flame Resistant and Thermal Insulating

1200°F / 648°C Continuous Exposure: Higher Intermittent

DeltaGlassä high temperature, heat & flame resistant knitted fiberglass sleeve is fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1200°F / 648°C. This sleeve provides protection for industrial wires, cables, hoses (hydraulics), tubing and pipes, along with providing thermal insulation and personnel protection.

This material resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18. This product is 100% Asbestos free. Non-Asbestos.

Knitted sleeve is less dense than the same size braided sleeve, but can provide similar spacing protection for hoses and cables as braided at a lower cost.

Available in By-The-Foot and in 100 foot lengths. Minimum order value (MOV) may apply to some By-The-Foot quantities.

Braided Fiberglass Sleeve - Premium Grade - Wire Cable Hose Pipe Protection

High Temperature, Heat & Flame Resistant and Thermal Insulating

1200°F / 648°C Continuous Exposure: Higher Intermittent

DeltaGlassä braided fiberglass sleeve is high temperature and heat resistant, and made from high quality type e-fiberglass that will not burn and will withstand continuous exposure to temperatures of 1200°F / 648°C. It provides excellent protection for industrial wires, cables, hydraulic hoses, tube and pipes and also provides thermal insulation and personnel protection.

This high temperature and heat resistant sleeve resists most alkalis and acids and is also unaffected by most bleaches and solvents. It is highly flexible and conformable. The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18. This product is 100% Asbestos free.

Available in By-The-Foot cut lengths and in 100 foot lengths. Minimum order value may apply to By-The-Foot quantities.

Braided Fiberglass Sleeve - Industrial Grade - Wire Cable Hose Pipe Protection

High Temperature, Heat & Flame Resistant and Thermal Insulating

1200°F / 648°C Continuous Exposure: Higher Intermittent

DeltaGlassä braided fiberglass sleeve is high temperature and heat resistant. Fabricated from high quality type-E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1200°F / 648°C. It provides excellent protection for industrial wires, cables, hoses (hydraulics), tube and pipes and also provides thermal insulation and personnel protection.

This is a general purpose industrial grade sleeve available in a Thin Wall version (1/16" wall thickness) and also a Thick Wall version (1/8"). Available By-The-Foot or in full spool lengths. This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable.

Braided Fiberglass Sleeve with Acrylic Saturant

High Temperature, Heat & Flame Resistant and Thermal Insulating

1200°F / 648°C Continuous Exposure: Higher Intermittent

DeltaGlassä high temperature and heat resistant fiberglass sleeve is a braided fiberglass (fibreglass / glassfibre) sleeve, fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1200°F / 648°C. It provides excellent protection for industrial wires, cables, hydraulic hoses, tube and pipes and also provides thermal insulation and personnel protection.

An acrylic saturant has been added to aid in handling and to add anti-fray properties. The saturant will smoke off at temperatures above 425F.

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18. This product is 100% Asbestos free.

Available By-The-Foot and in 100 foot lengths. Minimum order value may apply to By-The-Foot quantities.

Braided Fiberglass Sleeve Heat Treated

High Temperature, Heat & Flame Resistant and Thermal Insulating

1200°F / 648°C Continuous Exposure: Higher Intermittent

DeltaGlassä high temperature and heat resistant fiberglass sleeve is a braided fiberglass (fibreglass / glassfibre) sleeve, fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1200°F / 648°C.

It is further heat treated to remove loose fibers and to "set" the braid - making it easier to handle and install.

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18. This product is 100% Asbestos free.

Available By-The-Foot and in Spool lengths. Minimum order value may apply to By-The-Foot quantities.

Braided Fiberglass Spark Plug Ignition Wire Protection Sleeve / Boot

High Temperature, Heat & Flame Resistant and Thermal Insulating

1200°F / 648°C Continuous Exposure: Higher Intermittent

DeltaGlassä high temperature and heat resistant fiberglass sleeve is a braided fiberglass (fibreglass / glassfibre) sleeve, fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1200°F / 648°C.

Folded and stitched, it is designed to protect the ignition wire and spark plug from high heat from the engine manifold - preventing wire and plug failure in performance auto applications.

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18. This product is 100% Asbestos free.

Basalt Knit Sleeve for exhaust pipe and personnel protection

High Temperature, Heat & Flame Resistant and Thermal Insulating

1382°F / 750°C Continuous Exposure: Higher Intermittent

ExhaustSockä Basalt Knit Sleeve is a highly conformable sleeve which provides excellent thermal protection for engine and generator exhaust piping for automobiles, marine engines and generators, bus, construction and mining equipment.

Available in sizes from 1" ID up to 6" ID. Supplied in 100 foot lengths and easily cut to desired installation length. Good anti-fray and handling due to knitted construction.

· Helps maintain exhaust gas temperatures in order to meet

regulatory requirements.

· Knitted design allows for high conformability.

· Can be fabricated with apertures to accommodate brackets

and mounting pads.

· Available in pre-cut or continuous lengths.

· Expandable and durable - provides ease of installation.

· Conforms to bends, elbows, flex sections and flanges.

· Suitable for Fixed Generators, Marine Engines and Generators,

Automotive, Truck, Bus, Construction and Mining equipment.

regulatory requirements.

· Knitted design allows for high conformability.

· Can be fabricated with apertures to accommodate brackets

and mounting pads.

· Available in pre-cut or continuous lengths.

· Expandable and durable - provides ease of installation.

· Conforms to bends, elbows, flex sections and flanges.

· Suitable for Fixed Generators, Marine Engines and Generators,

Automotive, Truck, Bus, Construction and Mining equipment.

Vermiculite Coated Fiberglass Braided sleeve for wire cable & hose protection

High Temperature, Heat & Flame Resistant & Thermal Insulating

1500°F / 815°C Continuous Exposure: Higher Intermittent

FlameShieldä 1500 vermiculite coated fiberglass sleeve is a high temperature, heat and flame resistant thermal insulating sleeve that will withstand temperatures of up to 1500°F / 815°C continuous exposure. The base high temperature braided fiberglass sleeve is fabricated from high quality type E fiberglass that will not burn. The sleeve is then coated with a vermiculite dispersant.

This material resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The base fiber is manufactured to the specifications of ASTM D-578.

Applications for this product include thermal insulation, protection of industrial wires, cables, hose (hydraulics), tube and pipe as well as affording personnel protection and energy savings.

The vermiculite coating also adds abrasion resistance and anti-fray properties to the sleeve.

This sleeve is tested and certified to meet ASTM E 162, ASTM E 662 and SMP 800-C for surface flammability, smoke and toxic gas generation.

Braided Silica Sleeve for wire cable & hose protection

High Temperature, Heat & Flame Resistant & Thermal Insulating

1800°F / 982°C Continuous Exposure: Higher Intermittent

FlameShieldä InSilMaxä extreme high temperature, heat, flame, fire & pyro resistant braided silica sleeve/jacket is an excellent replacement to asbestos and ceramic sleeves or wrapping tape. This sleeve provides thermal insulation and protection for industrial wires, cables, hoses (hydraulics), tubes and pipes.

Highly durable and extremely flexible and has very low shrink when heated. A specialty coating provides excellent abrasion protection and adds to the tensile strength.

Woven from an extremely pure silica base fiber (SiO2) and can be used at 1800°F / 982°C continuously with excursions to 3000°F / 1650°C.

Can be layered with other materials for enhanced insulation protection.

Braided Small Diameter Precision Silica Sleeve for wire cable & hose protection

High Temperature, Heat & Flame Resistant & Thermal Insulating

1800°F / 982°C Continuous Exposure: Higher Intermittent

FlameShieldä InSilMaxä extreme high temperature, heat, flame, fire & pyro resistant braided small diameter precision silica sleeve/jacket is an excellent replacement to asbestos and ceramic sleeves or wrapping tape. This sleeve provides thermal insulation and protection for industrial wires, cables, hoses (hydraulics), tubes and pipes.

Highly flexible and durable this sleeve has very low shrink when heated.

Woven from a high purity silica base fiber (SiO2) and can be used at 1800°F / 982°C continuously with excursions to 3000°F / 1650°C.

Can be layered with other materials for enhanced insulation protection.

Alumina-Ceramic Braided Sleeve for wire cable & hose protection

Thermal insulating - High Temperature, Heat & Flame Resistant

2300°F / 1260°C Continuous Temperature Exposure with short duration higher intermittent exposure

FlameShieldä AluMaxä is an extreme high temperature, heat, fire and flame resistant high coverage braided alumina-ceramic sleeve. It is an excellent substitute for asbestos sleeves or wrapping tape. This alumina-ceramic sleeve provides both thermal insulation and protection for wires, cables, hoses (hydraulic), tubing and pipes.

This sleeve is highly durable and extremely flexible and exhibits a very low shrink coefficient when heated. A proprietary coating provides enhanced abrasion protection and adds to the tensile strength of the product.

The braid is fabricated from a high purity alumina base fiber (AL3O2) and can be used at temperatures up to 2300°F / 1260°C continuously with short excursions to 3000°F / 1650°C.

This braided sleeve can be layered with other materials for enhanced insulation protection over what it is covering.